COMPREHENSIVE SERVICES

As a system supplier for technologies of thread cutting, gauging, milling and clamping technology, we offer a broad range of services in addition to our standard product range. These include custom-made special tools, individual system solutions, regrinding service, recoating service, calibration service and many more.

TECHNICAL SERVICES

Emuge Franken Technical Services

For each of the EMUGE and FRANKEN brands there is a team of mechanical engineering experts ready to support our clients/partners with a wide range of services.

This includes:

The first level of support is Emuge Franken Precizni Alati BiH. The analysis of the problem and the support of our Technical Department is the first step, this contact can be made by phone, email or by coming to the address of the client/partner by the technical department of Emuga Franken Precizni Alati BiH.

The second level of support is the expert team of manufacturers Emuge and Franken;

Active support in the optimization of production processes;

Development and production of custom-made special tools;

Design of system solutions in cooperation with the Emuge Franken team;

Implementation and presentation of solutions, which includes:

Presentation of solutions, selection of tools, determination of optimal operating modes.

After recommendations and submitted solutions, arrival at the address of the client / partner where we implement, in practice, everything presented together. Training and operator training, etc.

To optimize the process in high-volume production, a laboratory is available at the manufacturer, where the expert team for technical support will test the tools on a certain material under similar conditions, in order to find the right solution.

MANUFACTURING SPECIAL TOOLS

Emuge Franken with a factory in Austria provides special tool manufacturing services according to the client’s request.

It often happens that in the process of making parts we have tools that are outside the standard dimensions, or if we want to avoid using more tools, e.g. use one instead of three tools, to avoid these situations the solution is to create a special tool according to the end user’s request. For these services, we have a Technical Department available that will analyze your requirements in detail and find the right solution. The delivery time for special tools is about 15 to 30 days. We make special tools only in VHM version, with and without coating. The program of tools which are offered:

- Drilling tools

- Step drills

- Milling tools

- Reamers

- and other.

REGRINDING AND RECOATING SERVICE

Regrinding and recoating is an important component for the economical use of cutting tools. Our regrinding and recoating service ensures that the original geometry and coating of a tool are restored.

Our service includes

- Customer consulting in your workshop or in our training rooms

- Regrinding service to the original manufacturer’s quality

- Recoating with the same coating as our new tools

- Short delivery times

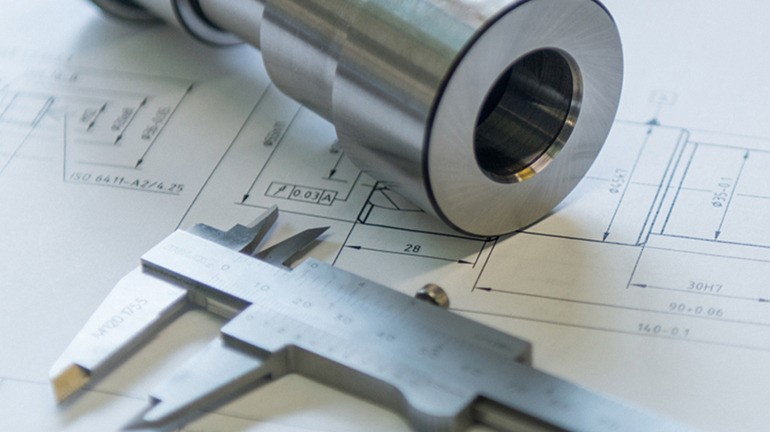

MEASURING EQUIPMENT CALIBRATION SERVICE

Test equipment monitoring

Our independent cooperation partner DECOM UGK is available at the EMUGE site to calibrate your testing and measuring equipment. The DECOM UGK has been a DAkkS-accredited testing laboratory for length and other geometric parameters (e.g. thread gauges, dial gauges, precision pointers, lever gauges, outside micrometers, calipers, etc.) in accordance with EN/ISO/IEC 17025 since 1998. EMUGE gauges can be equipped with a Factory or DAkkS calibration certificate can be supplied.

Reference standards and standard measuring devices:

Connection to national and international standards is ensured for all measurements carried out on behalf of customers. For this purpose, standards and standard measuring devices are kept ready, which are recalibrated at regular intervals by calibration centers recognized within the WECC.

EMUGE-FRANKEN Pecizni Alati serves as your contact and takes over the complete organization from the collection of the measuring equipment at your address to the delivery of the measuring instrument upon completion of the calibration process.

CLAMPING TECHNOLOGY

Tailor-made service for individual solutions

Clamping devices from EMUGE-FRANKEN work today in a wide variety of applications and industries.

Our range of services is correspondingly extensive: from standardized repairs to maintenance measures tailored to your needs.

We not only manufacture clamping devices, we also keep an eye on the “big picture”:

We advise you in a targeted manner and with professional expertise. Our clamping concepts are innovative and fit into your process. With commissioning by our experts, you enable a speedy and functioning start of production. To ensure that things “run smoothly” for you, we train your employees and keep your clamping devices in good condition with tailor-made maintenance measures.

Our service offers:

- Technical consultations

- Commissioning

- Training courses

- Maintenance and repairs

- On-site service calls

- Spare parts